Adhesives and Sealants

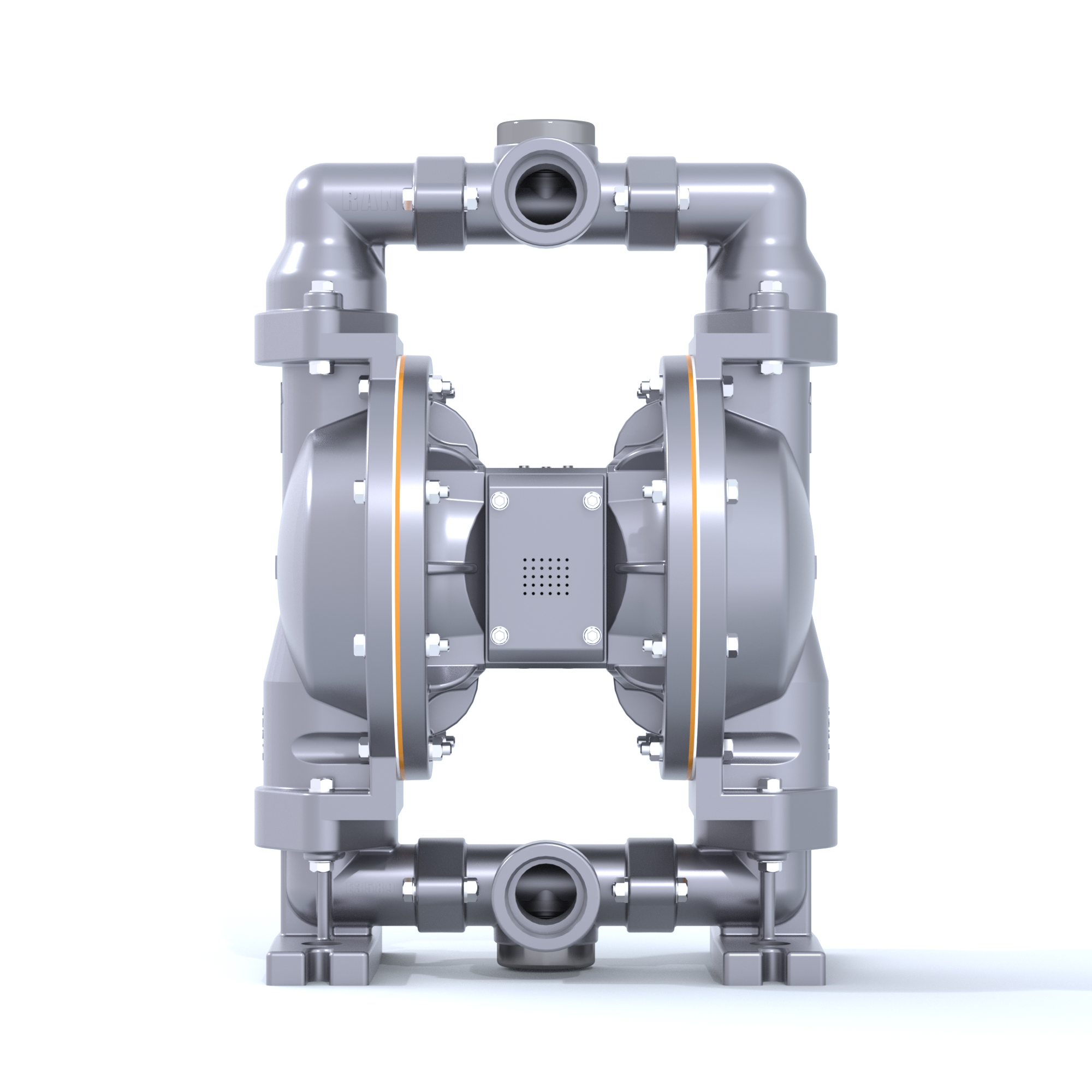

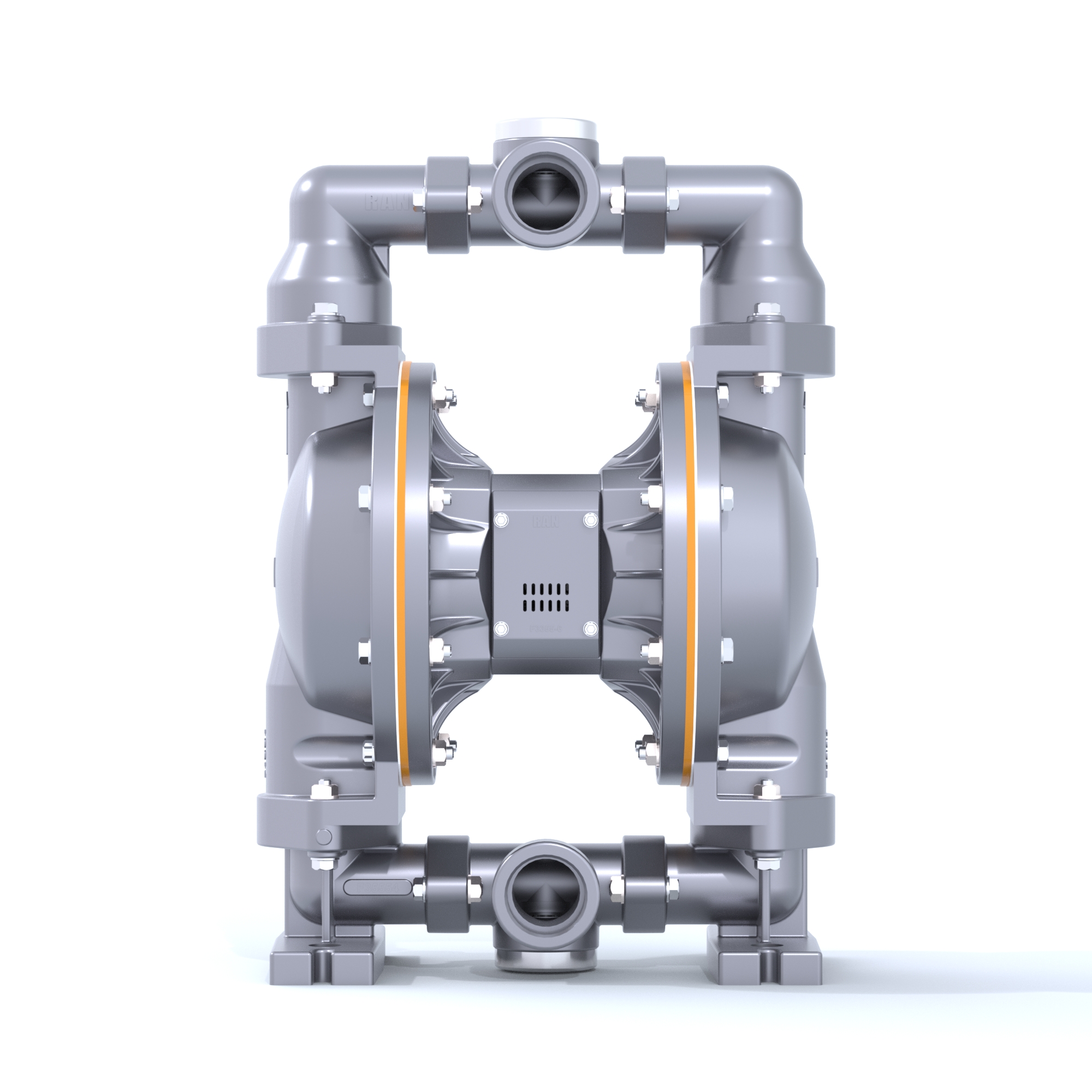

The Most Reliable Solution for Transferring Adhesives and Sealants: Air Operated Diaphragm Pumps

Adhesives and sealants are among the most critical materials in production processes. However, since these products are often high-viscosity, solvent-based, and difficult-to-handle fluids, choosing the right pump is essential. This is where air operated diaphragm pumps come into play!

Why Choose an Air Operated Diaphragm Pump?

- Reliable Performance Even with Challenging Fluids

Thick adhesives, mastics, or fillers… No matter the material, diaphragm pumps deliver smooth and efficient transfer with strong suction power.

- Protect Product Quality with Low Shear Handling

Your sensitive materials remain intact during transfer, ensuring consistent product quality every time.

- Safe Operation – ATEX Certified Options

For solvent-based and flammable chemicals, diaphragm pumps provide a completely air-driven solution without electric motors. Maximum safety in explosive environments.

- Easy Installation, Easy Maintenance

No need for complicated systems. With a simple design, diaphragm pumps are quick to install and maintenance or spare part replacement takes just minutes.

- Versatile Applications

From barrels to tanks, from production lines to filling stations – they fit seamlessly into every stage of your process.

Air operated diaphragm pumps combine reliability, durability, and efficiency in the transfer of adhesives and sealants.

If you want uninterrupted flow, safe operation, and low maintenance costs in your production line, the choice is clear: Air Operated Diaphragm Pumps!